An industrial bandsaw machine is a precision metal-cutting solution used across fabrication and manufacturing industries. This guide explains types, features, applications, buying considerations, maintenance strategies, and future trends, helping businesses choose efficient and reliable sawing solutions while improving productivity and operational accuracy.

Industrial Bandsaw Machines: A Complete Guide to Efficient Metal Cutting Solutions

Modern fabrication and manufacturing environments demand speed, precision, and cost efficiency. Traditional cutting tools often struggle to deliver consistent accuracy, especially when dealing with high-volume metal processing. Industrial buyers and workshop owners therefore require reliable sawing technology that balances productivity with long-term durability.

Bandsaw machines have emerged as one of the most efficient metal cutting solutions for industries ranging from automotive fabrication to heavy engineering. However, many buyers face confusion when selecting the right machine due to differences in automation levels, cutting capacity, and technological features.

This comprehensive guide explains how industrial bandsaw machines work, their key types, applications, and practical buying considerations — helping businesses make informed investment decisions.

What is a Bandsaw Machine?

A bandsaw machine is a power-driven cutting tool that uses a continuous looped blade with sharp teeth to cut metal or other materials with high precision. Unlike traditional circular saws, the bandsaw blade moves in one direction, enabling smoother cuts, reduced material waste, and consistent accuracy.

Industrial bandsaw machines are specifically designed for metal cutting applications such as steel bars, pipes, structural profiles, and solid billets. They offer controlled cutting speeds, automated feeding systems, and advanced coolant mechanisms to improve efficiency.

Key advantages include:

• Straight and accurate cutting performance

• Reduced kerf loss compared to abrasive cutting methods

• Energy-efficient operation

• Ability to handle heavy-duty industrial workloads

Because of these characteristics, bandsaw machines have become a core component of modern metal cutting workflows.

Types of Bandsaw Machines

Selecting the right type of bandsaw machine depends on production volume, material type, and automation requirements. Below are the most common industrial categories.

1. Horizontal Bandsaw Machines

Horizontal bandsaws are widely used for cutting long metal bars and structural components. The blade moves horizontally across the workpiece, making them suitable for batch production.

Best suited for:

• Steel service centers

• Fabrication workshops

• Heavy engineering units

2. Vertical Bandsaw Machines

Vertical models allow operators to guide materials manually, making them ideal for contour cutting or irregular shapes.

Advantages:

• Flexible cutting angles

• Suitable for custom fabrication work

• Useful in tool rooms and prototype workshops

3. Semi-Automatic Bandsaw Machines

Semi-automatic systems combine manual loading with automated cutting cycles. They improve productivity without requiring a full automation setup.

Ideal for:

• Medium-scale production facilities

• Job work manufacturers

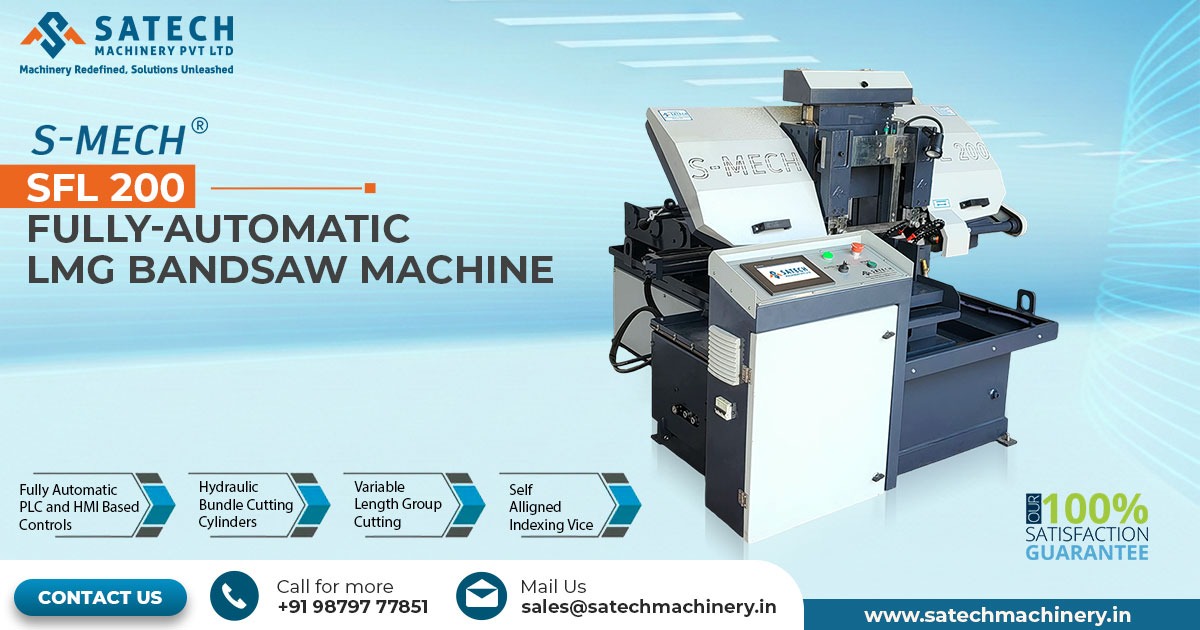

4. Fully Automatic Bandsaw Machines

Fully automatic machines are designed for high-volume industrial environments. They feature programmable controls, automatic feeding systems, and precise cutting cycles.

Benefits:

• Consistent production output

• Reduced labor dependency

• High repeatability for batch cutting

Key Features & Technology in Modern Bandsaw Machines

Industrial buyers increasingly prioritize technological innovation when evaluating sawing equipment. Advanced features improve accuracy, safety, and machine longevity.

Blade Technology

Modern bandsaw machines use bi-metal or carbide-tipped blades designed for durability and precision. Variable tooth pitch reduces vibration and enhances cutting performance.

Hydraulic Feed Control

Hydraulic systems regulate blade pressure and feed rate, preventing overheating while ensuring smooth operation.

CNC & Automation Integration

Programmable logic controllers (PLC) and CNC interfaces allow operators to set cutting parameters such as length, speed, and quantity. Automation reduces human error and improves productivity.

Coolant Systems

Integrated coolant delivery helps maintain blade temperature, extends tool life, and improves surface finish quality.

Energy Efficiency

New-generation industrial sawing machines focus on optimized motor efficiency and reduced power consumption, lowering operational costs.

Industrial Applications of Bandsaw Machines

Bandsaw machines are used across multiple manufacturing sectors due to their versatility and precision.

Metal Fabrication Industry

Fabricators rely on bandsaw machines to cut structural steel, pipes, and profiles before welding or assembly.

Automotive Manufacturing

Automotive suppliers use industrial sawing solutions to prepare components such as shafts, rods, and brackets.

Aerospace Engineering

Precision cutting is critical in aerospace manufacturing, where material waste and dimensional accuracy directly affect performance.

Construction & Infrastructure

Structural steel processing for bridges, buildings, and industrial plants often begins with accurate bandsaw cutting.

Tool & Die Workshops

Smaller workshops benefit from vertical bandsaws for detailed shaping and customized components.

Buying Guide: How to Choose the Right Bandsaw Machine

Choosing a bandsaw machine requires evaluating production goals, material types, and long-term operational efficiency. Consider the following decision factors.

Cutting Capacity

Determine the maximum size and type of material you plan to process. Machines vary based on cutting diameter, rectangular capacity, and weight handling.

Automation Level

High-volume operations benefit from fully automatic machines, while smaller workshops may prefer semi-automatic or manual options.

Blade Speed & Control

Variable speed control allows the machine to adapt to different materials such as mild steel, stainless steel, or alloy metals.

Structural Design

Rigid machine construction reduces vibration and improves cutting accuracy over time.

After-Sales Support

Reliable technical support, spare part availability, and maintenance assistance play a crucial role in long-term productivity.

Quick Comparison Table

| Machine Type | Production Volume | Operator Skill Required | Investment Level |

|---|---|---|---|

| Manual Bandsaw | Low | High | Low |

| Semi-Automatic | Medium | Moderate | Medium |

| Fully Automatic | High | Low | High |

| Vertical Bandsaw | Custom Work | Moderate | Medium |

Maintenance & Efficiency Tips for Industrial Bandsaw Machines

Proper maintenance directly impacts cutting performance and operational cost efficiency. Many productivity issues arise from poor blade care or incorrect machine setup.

Maintain Blade Alignment

Incorrect blade tension can lead to uneven cuts and premature wear. Regular inspection ensures consistent performance.

Optimize Coolant Usage

Proper coolant flow prevents overheating and extends blade life. Always monitor coolant levels during long cutting cycles.

Monitor Feed Rates

Excessive feed pressure reduces blade life and may damage materials. Adjust feed rates according to material hardness.

Routine Cleaning

Metal chips and debris can affect machine accuracy. Scheduled cleaning improves reliability and reduces downtime.

Preventive Maintenance Planning

Industrial environments benefit from structured maintenance schedules that include lubrication checks, hydraulic inspection, and electrical system evaluation.

Future Trends in Bandsaw Technology

Industrial sawing solutions continue to evolve as manufacturing shifts toward automation and digital integration.

Smart Monitoring Systems

IoT-enabled sensors can monitor vibration, blade condition, and performance metrics in real time. This allows predictive maintenance and reduces unexpected breakdowns.

AI-Driven Cutting Optimization

Advanced software can analyze material properties and automatically adjust cutting parameters, improving efficiency and consistency.

Sustainable Manufacturing

Energy-efficient motors and optimized cutting processes help manufacturers reduce operational costs while supporting environmental goals.

Integration with Industry 4.0

Bandsaw machines are increasingly connected with production management systems, enabling better workflow automation and data-driven decision-making.

Why Choose Satech Machinery Pvt. Ltd.

Selecting the right machinery partner is as important as choosing the right equipment. Satech Machinery Pvt. Ltd. focuses on delivering industrial sawing solutions designed for performance, reliability, and long-term value.

Key strengths include:

• Engineering-focused manufacturing approach

• Strong understanding of metal cutting applications

• Durable machine construction suitable for industrial workloads

• Practical design emphasizing efficiency and ease of operation

• Commitment to supporting fabrication and engineering industries

By combining technical expertise with industry-focused design, Satech Machinery Pvt. Ltd. provides solutions tailored to modern manufacturing needs.

FAQ: Industrial Bandsaw Machines

What is a bandsaw machine used for?

A bandsaw machine is primarily used for cutting metal bars, pipes, profiles, and solid materials with high accuracy and minimal waste.

How do I choose the right bandsaw machine?

Evaluate material type, production volume, automation needs, and cutting capacity. Businesses with high output requirements typically benefit from fully automatic systems.

Are bandsaw machines suitable for heavy-duty metal cutting?

Yes. Industrial bandsaw machines are specifically designed for heavy materials such as structural steel and alloy metals.

What are the benefits of industrial bandsaw machines?

They provide precise cuts, reduced material loss, improved productivity, and lower operational costs compared to traditional cutting methods.

How often should bandsaw machines be maintained?

Routine inspections should be performed weekly, while preventive maintenance schedules depend on production intensity and operating hours.

Can bandsaw machines improve manufacturing efficiency?

Yes. Automated feeding, programmable controls, and optimized blade technology significantly increase productivity.

What industries use bandsaw machines the most?

Metal fabrication, automotive, aerospace, construction, and general engineering workshops commonly rely on industrial bandsaw machines.

Conclusion

Industrial manufacturing continues to demand faster, more accurate metal cutting solutions. Bandsaw machines address these challenges by offering precision, efficiency, and adaptability across diverse applications. From small fabrication workshops to large-scale production facilities, choosing the right industrial sawing equipment can significantly improve operational performance.

With a focus on engineering quality and practical industrial design, Satech Machinery Pvt. Ltd. supports businesses seeking reliable bandsaw technology aligned with modern manufacturing standards. By understanding machine types, technological features, and maintenance practices, buyers can make informed decisions that drive long-term productivity and growth.