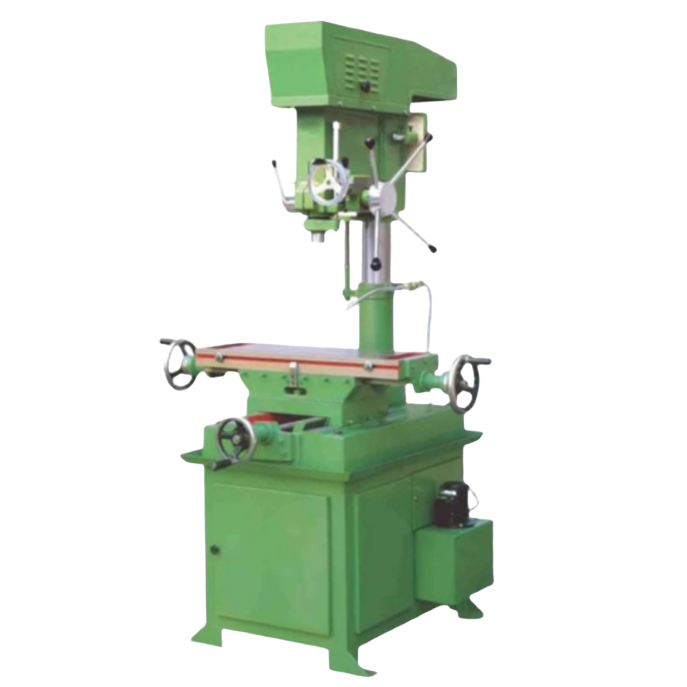

Home » Our Products » Drill Machine » Drilling Cum Milling » DCM-38

DCM-38

Features of DCM-38 Drilling Cum Milling

- The main spindle and pinion are made from steel by forging.

- The main spindle run out is checked for accuracy as per is 2199.

- All moving parts are fine-finished with grinding to a close tolerance.

- Main spindle NTN Japan makes bearings with grease with a grease bath, so for permanent oiling.

- The main gear and pulley are perfectly balanced.

- All gears are made from SGI casting and bearing drive.

- Accessories for longer life and preventing corrosion and pillage associated with usual chrome plating.

- Work table T-Slot machining.

- Designed with the operator in mind, the DCM-38 includes an intuitive control panel that simplifies operation.

- The DCM-38 seamlessly integrates drilling and milling capabilities, enabling users to switch between operations with ease.

Manufacturer and Supplier of the DCM-38 Drilling Cum Milling Machine in Ahmedabad India

Satech Machinery Pvt Ltd, based in Ahmedabad, India, is a distinguished manufacturer and supplier of advanced industrial machinery, including the highly versatile DCM-38 Drilling Cum Milling Machine. This innovative machine is designed to meet the diverse needs of various industries, including manufacturing, automotive, aerospace, and metalworking, providing a comprehensive solution for both drilling and milling operations.

The DCM-38 is engineered to deliver exceptional performance and precision, making it an indispensable tool for workshops and production facilities. This machine combines the functionalities of drilling and milling into a single unit, allowing operators to perform multiple tasks without the need for separate machines. This not only saves space but also enhances productivity and efficiency in the manufacturing process.

The machine is equipped with a high-performance motor that provides ample power for various materials, including metals, and composites. This ensures consistent performance even under heavy workloads. The machine offers adjustable speed and feed rates, allowing users to customize settings based on the specific requirements of their projects. This flexibility enhances the machine’s adaptability to various materials and applications.

Standard Accessories

- Motor Pully

- Drill Drift Key

Optional Accessories

- Electric Motor

- V-Belt

- R & F Switch

- Drill Chuck

- Arbour

- Coolant Pump With Tank

- Drill Vice

- Machine Lamp

Inquire Here

Technical Specifications

| Model | DCM-38 |

|---|---|

| Machine Capacity | |

| Machine Capacity | 38 |

| Face Mill | 60 |

| End Mill | 20 |

| Drilling Head | |

| Taper Spindle | M.T-4 |

| Spindle Travel | 240 |

| Speeds | |

| No. Range of Spindle | 8 |

| Spindle Speed (Min./Max.) | 70 to 2000 |

| Feeds | |

| No. Range of Feed | Manual |

| Working Range | |

| Distance from Spindle Centre to Column Face | 300 |

| Max. Distance From Spindle to Work Table | 500 |

| Slide of Traveling - X | 370 |

| Slide of Traveling - Y | 220 |

| Slide of Traveling - Y | 220 |

| Baste Plate & Column | |

| Column Diameter | 108 |

| Base Plate Diameter of Table | 255 x 830 |

| Base Area | 550 x 800 |

| No. of 't' Slots | 3 |

| Power Drilling Motor | 1.5 HP 1400 RPM |

| Weight (Kgs.) Approximate | 475 kg. |

| V-Belt (No.) | B-61 |