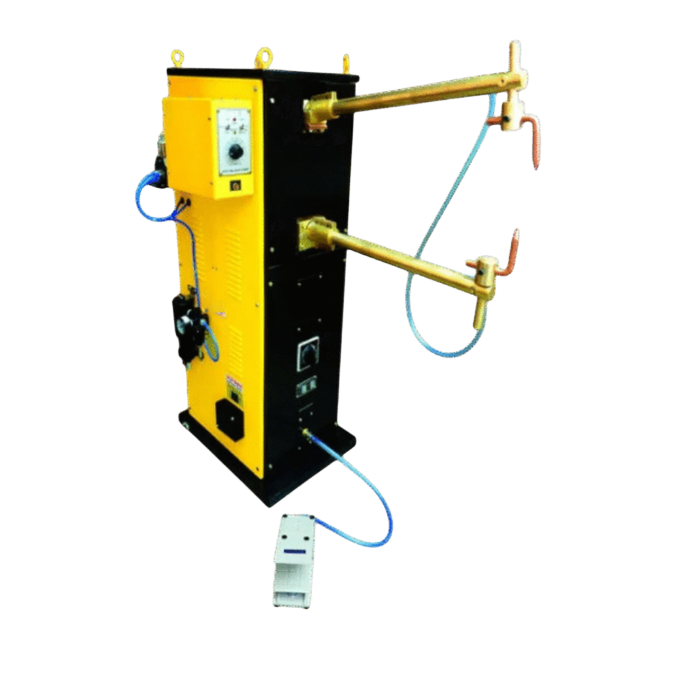

Home » Our Products » Welding Machine » Spot Welding Machine » Rocker Arm (Pneumatic Operated) Spot Welding

Rocker Arm (Pneumatic Operated) Spot Welding

- TRANSFORMER: Low leakage (High linkage) design, proper cooling and insulation, including winding varnishing by vacuum pressurized impregnating system to enhance reliability and service life.

- CURRENT CONTROL: Current setting from min. To max. can be done by 6 positions, offload the tap changing switch.

- TIME CONTROL: Solid State Electronic timer to control weld time from 5 to 50 cycles and 1 to 10 seconds to achieve accurate and repeatable spots.

- WELD PRESSURE: Adjustable max. Pressure levels are derived from a heavy-duty compression spring mounted on a pressure rod with an adjustable nut. Here is a special arrangement in the machine-minimises operator fatigue and ensures simple settings.

- COOLING: Electrodes and arms are provided with a water cooling arrangement with hose connections. (Water supply & coolant pump to be arranged by the user.)

- ELECTRODES: One pair of Morse Taper 2 straight electrodes made from hardened copper-alloy is supplied with the equipment. Other types of spare electrodes can be supplied on specific orders.

- CABINET: Modern looks, novel design concepts. Epoxy powder-coated body for rust-free, long life.

Rocker Arm (Pneumatic Operated) Spot Welding Manufacturer and Supplier in Ahmedabad India

The Rocker Arm (Pneumatic Operated) Spot Welding Machine from Satech Machinery Pvt Ltd represents a sophisticated solution for efficient and high-precision spot welding. Designed for industries that require rapid, reliable, and consistent welding of metal components, this advanced welding machine integrates cutting-edge pneumatic technology to enhance performance, ease of use, and versatility. The pneumatic operation ensures smooth, automated arm movement, enabling a more efficient and controlled welding process.

This machine is an ideal choice for manufacturers in sectors such as automotive, sheet metal fabrication, appliance manufacturing, and electronics, where high-speed, durable, and precise spot welding is essential. The Rocker Arm Spot Welding Machine combines reliable, long-lasting components with user-friendly features, making it an excellent addition to any production line.

Optional Accessories

- Welding Cable

- Earthing Clamp

- Welding Holder

- Lugs

- Welding Helmet

Inquire Here

Technical Specifications

| PARTICULARS | UNIT | VSP-6 | VSP-8 | VSP-10 | VSP-15 |

|---|---|---|---|---|---|

| Input Supply | Volts | 415 V, 1 Phase (2 lines of 3 phase supply), 50 Hzs. AC |

|||

| Rating @ 50% Duty Cycle | KVA | 6 | 8 | 10 | 15 |

| Nominal Throat Clearance | MM | 250 | |||

| Throat Depth | MM | 200, 300, 400 | 300, 400, 500 | 300, 400, 500 | 300, 400, 600 |

| Welding Range Mild Steel-Max.2x Thickness-Min.2x | MM MM | 2.0, 1.6, 1.0 0.3, 0.25, 0.1 | 2.5, 2.0, 1.25 0.35, 0.3, 0.2 | 3.0, 2.5, 1.5 0.4, 0.3, 0.2 | 3.5, 3.0, 1.0 0.6 0.5 0.3 |

| Brass Steel-Max.2x Thickness-Min.2x | MM MM | 0.8, 0.7, 0.45 0.17, 0.1, 0.08 | 1.0, 0.9, 0.6 0.2, 0.1, 0.08 | 1.2, 1.1, 0.75 0.25, 0.2, 0.12 | 2.0, 1.5, 0.9 0.3, 0.2, 0.1 |

| Stainless Steel-Max.2x Thickness-Min.2x | MM MM | 1.6, 1.4, 0.8 0.25, 0.2, 0.12 | 2.0, 1.8, 1.0 0.3, 0.25, 0.15 | 2.4, 2.2, 1.2 0.32, 0.28, 0.18 | 3.0, 2.4, 0.9 0.4, 0.3, 0.1 |

| Max. Available short ckt. Current | ΚΑ | 6.5, 5.5, 5 | 8, 7.5, 7 | 8.5, 7.5, 6 | 11, 10, 8 |

| Nominal Electrode Force (Approx) | Kg. | 150, 100, 75 | 150,100, 75 | 150, 100, 75 | 150, 100, 60 |

| Max. Electrode Stroke | MM | 70 | |||

| Insulation | Class | A (Copper Wound ) | |||

| Max. Dimensions Without Arm (Approx)(L, W, H) | MM MM MM | 600 390 1330 | 630 440 1330 |

||

| Weight Without Arm (Approx) | Kgs | 120 | 130 | 140 | 150 |

| Confirms to | IS-4804 (Part II) - 1968 | ||||

| Customers to provide the following services | |||||

| External Water supply at max. Temp. 30° C | Lit./Min | 3 | 5 | ||

| Size of mains Supply Copper Cable | MM² | 8 | 10 | 12 | 15 |

| Recommended Switch Rating | Amps | 30 | 45 | 63 | |

| Delayed Action Fuse Rating | Amps | 20 | 32 | 45 | |