Home » Our Products » Drill Machine » Pillar Drill Machine » PD-38

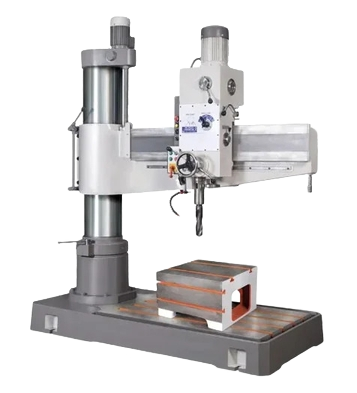

PD-38

Features of Pillar Drill Machine PD-38

- The main spindle and pinion are made from steel by forging.

- The PD-38 is designed for accurate drilling operations, ensuring that each hole is precisely placed and finished.

- Equipped with a robust motor, the PD-38 delivers consistent power for heavy-duty drilling tasks.

- Adjustable speeds for optimal drilling based on material type.

- Durable design minimizes vibrations and enhances stability.

- User-friendly controls reduce operator fatigue during extended use.

- Easily positioned to accommodate different workpieces.

- The machine features an adjustable work table that can be easily positioned to accommodate various workpieces.

- The PD-38 is versatile enough to handle a variety of materials, including metals.

- All moving parts are fine-finished with grinding to a close tolerance.

- The main gear and pulley are perfectly balanced.

- Work table T-Slot machining.

- All gears are made from SGI casting and bearing drive.

Manufacturer and Supplier of PD-38 Pillar Drilling Machine in Ahmedabad India

The PD-38 Pillar Drilling Machine, manufactured by Satech Machinery Pvt Ltd in Ahmedabad, Gujarat, is a high-performance drilling solution designed to meet the diverse needs of various industries. With a focus on precision, durability, and user-friendliness, the PD-38 is an essential tool for metalworking, and fabrication tasks. Satech Machinery, a trusted name in the machinery manufacturing sector, has engineered the PD-38 to deliver exceptional performance, making it a valuable addition to any workshop or manufacturing facility.

PD-38 Pillar Drilling Machine from Satech Machinery Pvt Ltd is a high-performance drilling solution that combines precision, durability, and user-friendly features. Safety is a top priority in the design of the PD-38. The machine includes essential safety features such as emergency stop buttons, protective guards, and overload protection to ensure a safe working environment for operators. The PD-38 is designed for easy maintenance, with accessible components that simplify routine checks and servicing. This ease of maintenance helps keep the machine in optimal working condition, reducing downtime and enhancing productivity.

Standard Accessories

- Motor Pully

- Drill Drift Key

Optional Accessories

- Electric Motor

- V-Belt

- R & F Switch

- Drill Chuck

- Arbour

- Coolant Pump With Tank

- Drill Vice

- Machine Lamp

Inquire Here

Technical Specifications

| Model | PD38 |

|---|---|

| Machine Capacity | |

| Drilling (C.I.) | 38 |

| Drilling (M.S.) | 38 |

| Tapping Cap. | 20 |

| Drilling Head | |

| Tapper Spindle | M.T-4 |

| Quil Movement | 240 |

| Speeds | |

| No. Range of Spindle | 8 |

| Spindle Speed (Min./Max.) | 70 to 2000 |

| Feeds | |

| No. Range of Feed | Manual |

| Working Range | |

| Dist. From Spindle Centre to Column Face | 300 |

| Max. Dist. From Spindle to Base Pite | 100 |

| Max. Dist. From Spindle to Work Table | 530 |

| Working Table | |

| Table Diameter | 422 X 422 |

| Baste Plate & Column | |

| Column Diameter | 108 |

| Base Plate | 680 X 430 |

| No. of 't' Slots | 2 |

| Power Drilling Motor | 1.5 HP / 1400 RPM |

| Weight (Kgs.) Approximate | 350 kg. |

| V-Belt (No.) | B-60 |