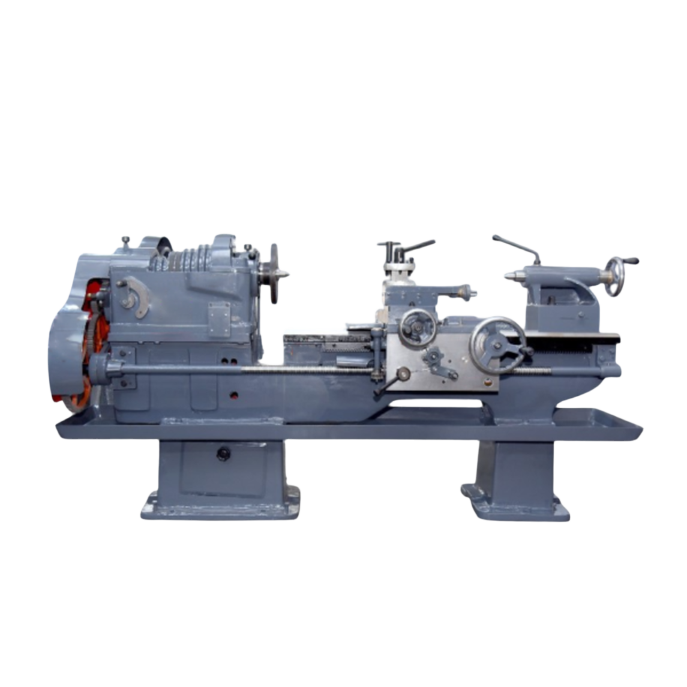

Home » Our Products » Lathe Machine » V-Belt Drive Lathe Machine » Heavy Duty Lathe Machine

Heavy Duty Lathe Machine

- Designed with a heavy-duty cast iron body for high stability and vibration-free operation.

- Ensures smooth power transmission with minimal energy loss for efficient machining.

- High-quality spindle with accurate alignment for precise and consistent performance.

- Advanced gear system with multiple speed options for versatile machining applications.

- Hardened and ground bedways provide durability and enhanced wear resistance.

- Accommodates large workpieces with ease, suitable for various industrial applications.

- Equipped with automatic longitudinal and cross-feed options for precise control.

- Adjustable tailstock ensures accurate support for long workpieces.

- Proper lubrication ensures smooth operation and extends machine life.

- Ergonomic design with easy-to-use control levers for operator convenience and safety.

Heavy Duty Lathe Machine Manufacturer and Supplier in Ahmedabad India

The Heavy Duty Lathe Machine (V-Belt Drive Category) is a high-performance industrial lathe designed for heavy-duty machining applications. Engineered with precision and durability, this machine is ideal for industries requiring accurate turning, facing, and threading of large workpieces. With a robust construction and advanced V-Belt drive mechanism, it ensures smooth power transmission, reduced vibrations, and enhanced operational efficiency.

The V-Belt drive system ensures smooth and efficient power transmission, reducing energy loss and providing consistent torque for various machining applications. This system allows the machine to operate at optimal speed without compromising on performance or precision.

Equipped with a high-speed gearbox, this lathe provides multiple speed variations, making it suitable for working with different materials, from soft metals to hardened alloys. The easy-to-adjust speed control mechanism allows operators to switch between speed settings efficiently for precise cutting and finishing.

Standard Accessories

- chuck back plate

- center adapter

- thread dial indicator

- dead center-2 nos

- nylon flat belt

- chip tray

- change gear set-1 (for metric and inch)

- R/F switch

- motor pulley

- v-belt-2 nos

- tool post key

Optional Accessories

- Face plate

- Carrier plate

- steady rest

- follow rest

- Taper turning attachment

- coolant pump with tank and fittings

- Rear tool post

- norton gear box

- three-speed gear box

- six-speed gear box

- electric motor

Inquire Here

Technical Specifications

| MODEL | SHDL0 | SHDL1 | SHDL2 | SHDL3 | SHDL4 | SHDL5 | SHDL6 |

|---|---|---|---|---|---|---|---|

| Length of Bed | 1675 m.m. (5’-6”) | 2135 m.m. (7’) | 2745 m.m. (9’) | 3050 m.m. (10’) | 3655 m.m. (12’) | 4250 m.m. (14’) | 4850 m.m. (16’) |

| Admit Between Center | 500 m.m. | 965 m.m. | 1575 m.m. | 1905 m.m. | 2515 m.m. | 3100 m.m. | 3710 m.m. |

| Center Height Over Flat Bed Ways | 255 m.m (325 m.m) / 305 m.m (375 m.m) | 255 m.m (325 m.m) / 305 m.m (375 m.m) | 255 m.m (325 m.m) / 305 m.m (375 m.m) | 255 m.m (325 m.m) / 305 m.m (375 m.m) | 255 m.m (325 m.m) / 305 m.m (375 m.m) | 255 m.m (325 m.m) / 305 m.m (375 m.m) | 255 m.m (325 m.m) / 305 m.m (375 m.m) |

| Swing Over Bed | 480 m.m (325 m.m) / 600 m.m (375 m.m) | 480 m.m (325 m.m) / 600 m.m (375 m.m) | 480 m.m (325 m.m) / 600 m.m (375 m.m) | 480 m.m (325 m.m) / 600 m.m (375 m.m) | 480 m.m (325 m.m) / 600 m.m (375 m.m) | 480 m.m (325 m.m) / 600 m.m (375 m.m) | 480 m.m (325 m.m) / 600 m.m (375 m.m) |

| Swing Over Cross Slide | 285 m.m (325 m.m) / 375 m.m (375 m.m) | 285 m.m (325 m.m) / 375 m.m (375 m.m) | 285 m.m (325 m.m) / 375 m.m (375 m.m) | 285 m.m (325 m.m) / 375 m.m (375 m.m) | 285 m.m (325 m.m) / 375 m.m (375 m.m) | 285 m.m (325 m.m) / 375 m.m (375 m.m) | 285 m.m (325 m.m) / 375 m.m (375 m.m) |

| Swing in Gap | 785 m.m (325 m.m) / 910 m.m (375 m.m) | 785 m.m (325 m.m) / 910 m.m (375 m.m) | 785 m.m (325 m.m) / 910 m.m (375 m.m) | 785 m.m (325 m.m) / 910 m.m (375 m.m) | 785 m.m (325 m.m) / 910 m.m (375 m.m) | 785 m.m (325 m.m) / 910 m.m (375 m.m) | 785 m.m (325 m.m) / 910 m.m (375 m.m) |

| No. Of Spindle Speed | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Spindle Speed Range | 30 To 550 RPM | 30 To 550 RPM | 30 To 550 RPM | 30 To 550 RPM | 30 To 550 RPM | 30 To 550 RPM | 30 To 550 RPM |

| Spindle Morse Taper | MT-6 | MT-6 | MT-6 | MT-6 | MT-6 | MT-6 | MT-6 |

| Spindle Bore | 52 m.m./80 m.m./105 m.m. | 52 m.m./80 m.m./105 m.m. | 52 m.m./80 m.m./105 m.m. | 52 m.m./80 m.m./105 m.m. | 52 m.m./80 m.m./105 m.m. | 52 m.m./80 m.m./105 m.m. | 52 m.m./80 m.m./105 m.m. |

| Spindle Nose | Threaded | Threaded | Threaded | Threaded | Threaded | Threaded | Threaded |

| Lead Screw Diameter / Pitch | 38.1 m.m./4 TPI | 38.1 m.m./4 TPI | 38.1 m.m./4 TPI | 38.1 m.m./4 TPI | 38.1 m.m./4 TPI | 38.1 m.m./4 TPI | 38.1 m.m./4 TPI |

| Range Of British Threads | 2 to 20 TPI | 2 to 20 TPI | 2 to 20 TPI | 2 to 20 TPI | 2 to 20 TPI | 2 to 20 TPI | 2 to 20 TPI |

| Range Of Matric Threads | 1 to 6 m.m. | 1 to 6 m.m. | 1 to 6 m.m. | 1 to 6 m.m. | 1 to 6 m.m. | 1 to 6 m.m. | 1 to 6 m.m. |

| Tail Stock Spindle Diameter | 50.8 m.m. | 50.8 m.m. | 50.8 m.m. | 50.8 m.m. | 50.8 m.m. | 50.8 m.m. | 50.8 m.m. |

| Taper in Tail Stock Quill | MT-4 | MT-4 | MT-4 | MT-4 | MT-4 | MT-4 | MT-4 |

| Tail Stock Spindle Travel | 180 m.m. | 180 m.m. | 180 m.m. | 180 m.m. | 180 m.m. | 180 m.m. | 180 m.m. |

| Compound Slide Travel | 145 m.m. | 145 m.m. | 145 m.m. | 145 m.m. | 145 m.m. | 145 m.m. | 145 m.m. |

| Tool Post Square | 120 x 120 m.m. | 120 x 120 m.m. | 120 x 120 m.m. | 120 x 120 m.m. | 120 x 120 m.m. | 120 x 120 m.m. | 120 x 120 m.m. |

| Tool Shank Size | 25 x 25 m.m. | 25 x 25 m.m. | 25 x 25 m.m. | 25 x 25 m.m. | 25 x 25 m.m. | 25 x 25 m.m. | 25 x 25 m.m. |

| Electric Motor (Optional) | 3 HP / 5HP (3 Phase) | 3 HP / 5HP (3 Phase) | 3 HP / 5HP (3 Phase) | 3 HP / 5HP (3 Phase) | 3 HP / 5HP (3 Phase) | 3 HP / 5HP (3 Phase) | 3 HP / 5HP (3 Phase) |