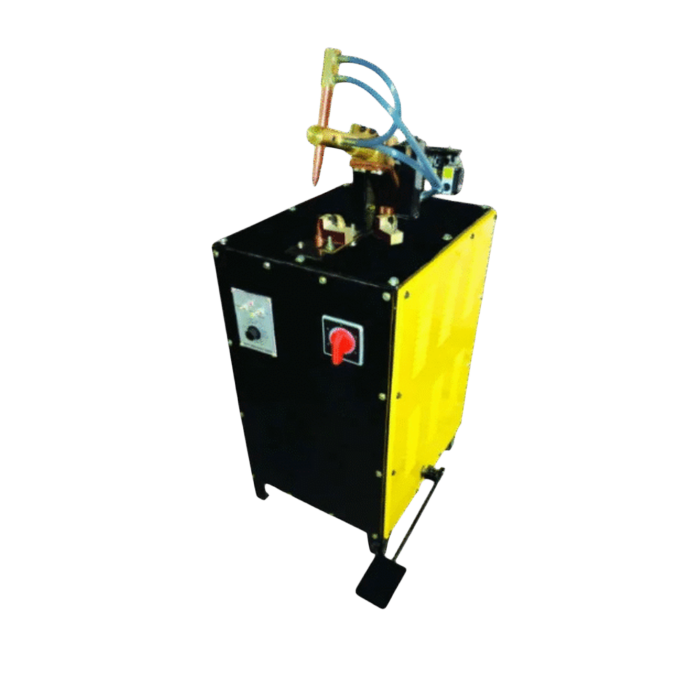

Home » Our Products » Welding Machine » Spot Welding Machine » Pedal Operated Table Type Spot Welding

Pedal Operated Table Type Spot Welding

- TRANSFORMER: Low leakage (High linkage) design, proper cooling and insulation, including winding varnishing by vacuum pressurized impregnating system to enhance reliability and service life.

- CURRENT CONTROL: Current setting from min. To max. can be done by 6 positions, offload the tap changing switch.

- TIME CONTROL: Solid State Electronic timer to control weld time from 5 to 50 cycles and 1 to 10 seconds to achieve accurate and repeatable spots.

- WILD PRESSURE: Adjustable max. Pressure levels are derived from a heavy-duty compression spring mounted on a pressure rod with an adjustable nut. Here is a special arrangement in the machine-minimises operator fatigue and ensures simple settings.

- ELECTRONICS: One pair of Morse Taper 2 straight electrodes made from hardened copper-alloy is supplied with the equipment. Other types of spare electrodes can be supplied on specific orders.

- CABINET: Modern looks, novel design concepts. Epoxy powder-coated body for rust-free, long life.

Pedal Operated Table Type Spot Welding Manufacturer and Supplier in Ahmedabad India

The Pedal Operated Table Type Spot Welding Machine from Satech Machinery Pvt Ltd is a precision-engineered solution designed for a wide range of spot welding applications in various industries. Combining simplicity, efficiency, and robust performance, this machine is ideal for smaller-scale production lines, repair work, and manufacturing settings where flexibility, safety, and control are crucial. The pedal-operated system offers operators greater convenience and precision in initiating welding cycles, while the table-type design provides stability and ease of access to the workpieces.

Built to cater to industries like automotive, metalworking, electronics, and appliance manufacturing, the Pedal Operated Table Type Spot Welding Machine is crafted to ensure high-quality welds with ease of operation and minimal maintenance. The user-friendly design, coupled with its superior weld capabilities, makes this machine an essential tool for any workshop or production environment focused on delivering strong, reliable welds with consistency and speed.

Optional Accessories

- Welding Cable

- Earthing Clamp

- Welding Holder

- Lugs

- Welding Helmet

Inquire Here

Technical Specifications

| PARTICULARS | UNIT | VST-6 | VST-8 | VST-10 |

|---|---|---|---|---|

| Input Supply | Volts | 415V, 1 Phase (2 lines of 3 Phase Supply), 50 Hzs, AC | ||

| Rating @ 50% Duty Cycle | KVA | 6 | 8 | 10 |

| Nominal Throat Clearance | MM | 150 | ||

| Throat Depth | MM | 200, 300 | 200, 300 | 200, 300 |

| Welding Range Mild Steel-Max.2x Thickness-Min.2x | MM MM | 2.0, 1.6 0.3, 0.25 | 2.5, 2.0 0.35, 0.3 | 3.0, 2.5 0.4, 0.3 |

| Brass Steel-Max.2x Thickness-Min.2x | MM MM | 0.8, 0.7 0.17, 0.1 | 1.0, 0.9 0.2, 0.1 | 1.2, 1.1 0.25, 0.2 |

| Stainless Steel-Max.2x Thickness-Min.2x | MM MM | 1.6, 1.4 0.25, 0.2 | 2.0, 1.8 0.3, 0.25 | 2.4, 2.2 0.32, 0.28 |

| Max. Available short ckt. Current | ΚΑ | 6.5, 5.5 | 8, 7.5 | 8.5, 7.5 |

| Nominal Electrode Force (Approx) | Kg. | 100, 75 | 100, 75 | 100, 75 |

| Max. Electrode Stroke | MM | A (Copper Wound) | ||

| Insulation | Class | |||

| Max. Dimensions Without Arm (Approx)(L, W, H) | MM MM MM | |||

| Weight Without Arm (Approx) | Kgs | |||

| Confirms to | IS-4804 (Part II) - 1968 | |||

| Customers to provide the following services | ||||

| Size of mains Supply Copper Cable | MM² | 8 | 10 | 12 |

| Recommended Switch Rating | Amps | 30 | 40 | |

| Delayed Action Fuse Rating | Amps | 20 | 25 | |